MARS-EXG-2012

| Availability: | |

|---|---|

| Quantity: | |

Main Components:Steel movement, water jacket,OLED display,protecting cover, water adapter, air purge gas joint, water adaptor,mounting bracket.

The MARS series of one color industrial pyrometer measure the temperature of an object by receiving the sum of the energy it emits in a narrow band.It adopts advanced software and hardware design, with super wide dynamic range and high stability.

It can be widely used in forging industry, steel mill heat treatment, induction heating, vacuum furnace, high temperature furnace, monocrystalline silicon, polycrystalline silicon and other industrial temperature measurement.

Features of Mars series Infrared pyrometer Temperature range covering 200℃~3000℃. |

|

Principle of One Color Infrared Pyrometer

At present, one color pyrometers on the market are mostly narrow-band pyrometers.The principle of temperature measurement is to determine the temperature of an object by the amount of radiation energy occurring within a narrow wavelength range.with measuring an average temperature in an area, values is affected by emissivity, lens contamination and background radiation.

The amount of radiant energy emitted by an object is related to its emissivity. The higher the emissivity, the more infrared energy the object emits.The emissivity of an object is related to the state of the object surface. The surface roughness, the degree of brightness and darkness, and different materials all affect the emissivity. Therefore, when using a monochromatic pyrometer, there is often a table of emissivity of different materials.

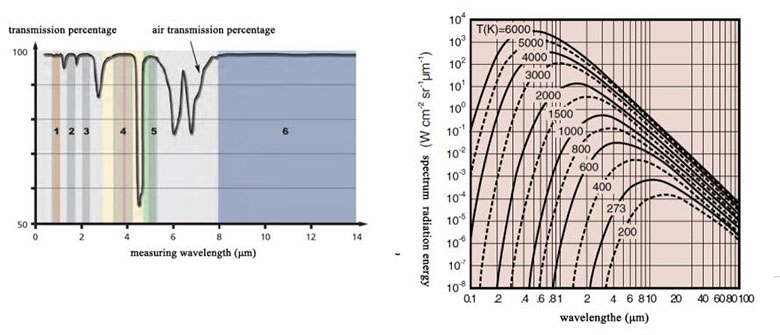

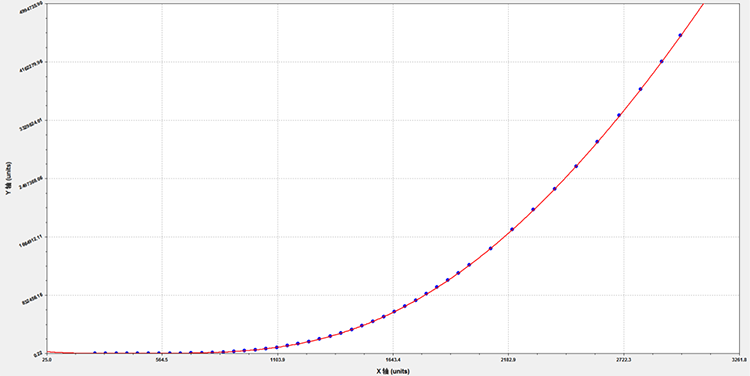

250 ~ 3000°C InGaAs detector characteristic curve, signal dynamic range 2.1 million times

Changes in emissivity, lens contamination, and the effects of background radiation are related to the choice of wavelength. Choose special wavelength range can enable the one color pyrometer overcome the interference of transmission medium as much as possible. Such as the influence of water vapor, various gases and other substances.Choose short wavelength can minimize the influence of emissivity. | Different types of detector selected under different atmospheric Window1SiWindow2Ge, InGaAsWindow3PbS,ExInGaAsWindow4PbSe,ThermopileWindow5ThermopileWindow6 |

Technical Parameters

Model | MARS-EXG-2012 |

Measuring Range | 200℃~1200℃ |

Detector | InGaAs(Extended Indium gallium arsenic) |

Wavelength | (1.45~2.1) μm |

Applications | Nonferrous metal processing、 |

Distance coefficients | 100:1 |

Accuracy | ±0.5%T℃(T is measured temperature) |

Resolution | 0.1℃ |

Repeat Accuracy | ±2℃ |

One-color coefficient | 0.100~1.000, Adjustable in 0.001 increments |

Response time | Fasted: 5ms,adjustable in 5ms-99.99s |

Output | Multiple annalog output 16bit (4mA~20mA,0mA~20mA,0V~5V,0V~10V option)Resolution 0.1℃,Current loop output maximum load 600Ω, Voltage output allowed current 10mA Alarm output:Upper limit、Lower limit alarm,with photocouple relay has unlimited service life,On resistance≤1Ω,maximum allowed voltage: AC42V or DC60V,Maximum allowed current:100mA,Response time: 2ms. RS485 output,capable parameter modification, data recording and query function |

Display mode | Industrial-grade self-luminous OLED display screen (default) or visual eyepiece aiming |

Aiming method | Built-in visible high brightness green light or eyepiece aiming |

IP Rating | IP65 |

Applications

The measured object has a large measuring area (fully capable of filling the target field of view), a flat surface (without bending), a measuring direction less than 30 degrees, a stable physical and chemical state on the surface of the measured object (not in the process of oxidation, gasification or liquefaction), less dust in the optical channel, and no obstruction or attenuation.

Technical Parameter of MARS-G series

Model | MARS -G-2511 | MARS -G-3014 | MARS -G-3520 | MARS -G-3525 | MARS -EXG-2012 |

Measuring range(℃) | 250~1100 | 300~1400 | 350~2000 | 350~2500 | 200~1200 |

Detector | InGaAs(Indium gallium arsenic) | InGaAs(Extended Indium gallium arsenic) | |||

Working wavelength | (1.45~1.7)μm | (1.45~2.1)um | |||

Mostly application | Heat treatment、Galvanized wire、Nonferrous metal processing、annealing furnace | Induction heating、heat treatment、monocrystalline、 polycrystalline、vacuum furnace、high temperature furnace | Nonferrous metal processing、 Induction heating、coating | ||

Distance coefficient | 60:1 | 100:1 | 200:1 | 100:1 | |

Measuring coefficient | Standard focus distance0.35m to infinity adjustable,near focus distance 0.15m to 0.5m adjustable | ||||

Measuring accuracy | ±0.5%T℃(T as temperature measuring value) | ||||

Temperature resolution | 0.1℃ | ||||

Repeat accuracy | ±2℃ | ||||

One-color coeffient | 0.100~1.000,Adjustable in 0.001 increments | ||||

Response time | 5ms~99.99s,capable adjustable | ||||

Signal processing | Peak value、valley value、Average value,ambient temperature too haigh and too low alarm,power down protection and others function etc. | ||||

Output | Multiple annalog output 16bit (4mA~20mA,0mA~20mA,0V~5V,0V~10V option), Resolution 0.1℃,Current loop output maximum load 600Ω, Voltage output allowed current 10mA | ||||

Alarm output:Upper limit、Lower limit alarm,with photocouple relay has unlimited service life, On resistance≤1Ω,maximum allowed voltage: AC42V or DC60V,Maximum allowed current:100mA,Response time: 2ms | |||||

RS485 output,capable parameter modification, data recording and query function | |||||

Display mode | With self-illumination industrial gread OLED display screen | ||||

Power supply | DC(20~30)V,power consumption:5W(24V@200mA),With over voltage, over current, short circuit protection,With Built-in EMI filter、can resist 2500VDCpalus group interferance. | ||||

Ambient temperature compensation | Built-in ambient temperature compensation, almost unaffected by ambient temperature changes. | ||||

Aiming mode | Built-in visible high brightness green light or eyepiece aiming | ||||

Interface | With fully sealed plug | ||||

Service environment | -20℃~+60℃,without water cooling;-20℃~+200℃,with water cooling | ||||

IP rate | IP65 | ||||

In May 2024, Laan Protection Technology Co., Ltd. completed the ISO 45001 system recertification. The audit team recognized the company's hazard identification and risk control in R&D, production and warehousing, confirming that the system operates effectively and records are complete. The company w

1. Infrared temperature measurement is a means of detecting equipment temperature anomaly. It is a non-contact temperature measurement method, which shows the temperature of the object by measuring the infrared light radiated by the object.Infrared is infrared radiation, infrared or infrared light f

The 14th Photonic China Expo, Beijing 2023, recently concluded with great success. This expo attracted numerous companies and experts focused on the infrared photonics field, bringing about new breakthroughs and collaboration opportunities for the industry. During the exhibition, we had the privileg

Changzhou Sijie Optoelectronics Technology Co., Ltd., a leading manufacturer of Infrared Pyrometer in China with an unwavering commitment to delivering superior accuracy and value, we are poised to meet this growing demand.In recent times, an increasing number of Indian companies have shown keen int