Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0519-85506598

Introduction

Metallurgical production enterprises not only have a very close relationship with the temperature, but also it is a comprehensive system of enterprises, in addition to special metallurgical equipment such as metallurgical kiln, there are electric power, electrical appliances and raw material chemical and other auxiliary equipment. Once the failure of these key equipment, it will not only cause huge economic losses, but also easy to cause harm to the staff.

Using infrared imaging technology to detect the equipment, understand and master the status of the process of equipment use, as early as possible to find out the cause of problems, to ensure safe production and operation, prolong the service life of equipment has an important significance.

Equipment pre-maintenance

Equipment pre-maintenance (motor, bearing, fan, electrical equipment testing, etc.), production equipment online operation and maintenance, online maintenance, spare parts offline repair, spare parts new manufacturing, equipment installation, debugging, etc.

Temperature testing of ladle resistant material

Long-term erosion of refractory material inside ladle by high temperature molten steel will lead to thinning of ladle wall, which is easy to cause leakage accident through ladle. At the same time, the surface temperature of ladle will increase due to the thinning of ladle wall. The higher the thinning degree, the higher the surface temperature. The surface temperature of the ladle can be measured by thermal imager, and the thickness of the ladle wall can be deduced back, and the corresponding maintenance measures can be taken to prevent the ladle piercing.

Detection of water wall defect of blast furnace lining

The infrared thermal imager can detect the partition block on the surface of the blast furnace and analyze the temperature distribution of the obtained infrared thermal imager. For the part without cooler, through the different changes of furnace surface temperature, it can be directly judged that there is no lining defect. If the temperature of a heat map taken at a certain location continues to rise, it can be determined that the furnace lining has been damaged and eroded. For the part where the cooler exists, the surface temperature distribution can be analyzed according to the heat map to find out the part where the relative temperature rises and judge the damage of the cooling wall or the defect of the furnace lining.

Temperature detection of resistant material in converter

The converter structure only has the furnace shell and lining, without the cooling part. By analyzing the surface temperature of the converter skin, the erosion damage degree of furnace lining can be judged directly after the thermal map of the converter skin is taken by infrared thermal imager.

Hot Blaster

Because of its arc shape, hot blast stove, especially the vault part, is prone to crack and fall off in the production of thermal insulation material firebrick, which may cause the shell to burn through and lead to safety accidents in serious cases. The damaged position of the arch lining can be detected quickly and accurately by using the thermal imager, which is convenient for timely maintenance and safe production.

Rotary Kiln

According to the abnormal part of high temperature on the infrared thermal image, the inner lining of the corresponding part of high temperature can be diagnosed immediately. The higher the temperature is, the more serious the corresponding defect is.

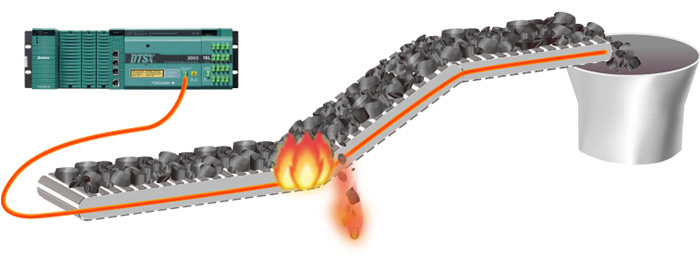

Fire prevention monitoring of sintering conveyor belt

The sintered clinker is transported to the blast furnace through the conveyor belt. In the process of transportation, the sinter may not be cooled properly (the temperature after normal cooling is 80-100℃). In the process of transportation, high-temperature sinter will easily ignite the belt, resulting in the burning down of the whole ore transport system and heavy losses.

Temperature detection of resistant material of torpedo tank car

Detect the crack, bulge and fall off caused by chemical erosion, mechanical scour and rapid cooling and heat of torpedo tank car lining. When partial damage to refractories is severe and goes undetected, it can cause serious accidents. Thermal imager is used for preventive detection to avoid accidents.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.