MIL20-A

| Availability: | |

|---|---|

| Quantity: | |

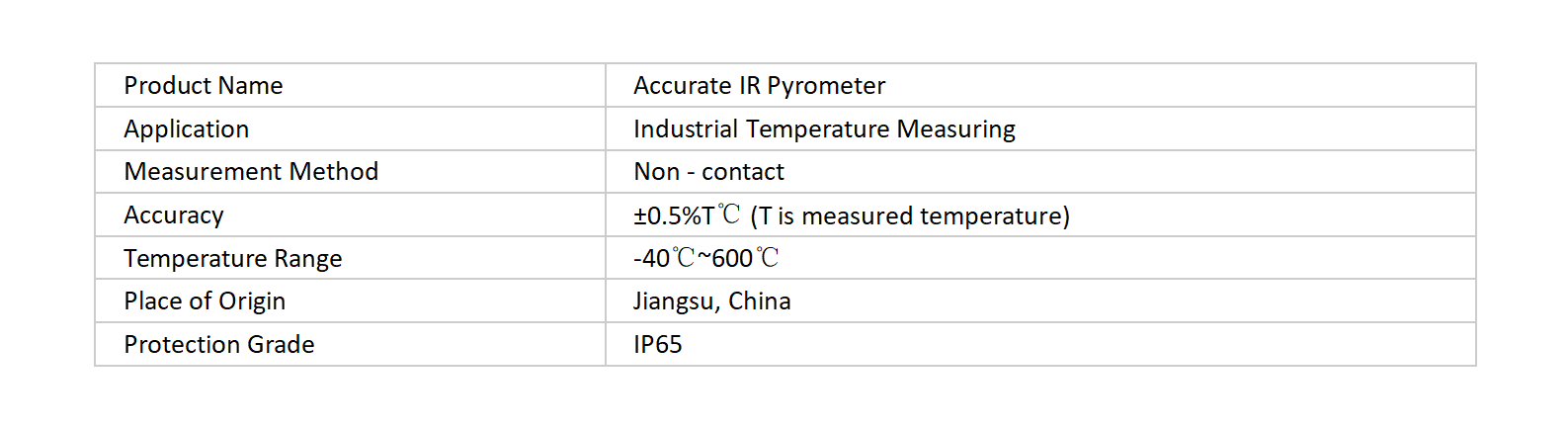

Accurate IR Pyrometer for High Temperature Measurement in Glass Melting Processes

This High Temperature IR Pyrometer offers precise and reliable thermal readings without direct contact, making it ideal for monitoring molten materials during industrial processes. Its advanced sensor technology ensures accurate data collection even under extreme conditions, providing users with real-time insights into their operational efficiency.

This product is engineered to withstand harsh environments, including intense heat, dust, and varying atmospheric conditions. The IR Pyrometer for Glass Melting is equipped with a robust housing that protects internal components from damage while maintaining optimal performance. Whether used in furnace operations or as part of an automated control system, this device delivers consistent results that support quality assurance and process optimization.

The High Temperature IR Pyrometer is built with precision in mind, featuring advanced signal processing algorithms that filter out noise and interference. This ensures that the readings are not only accurate but also stable over extended periods. Additionally, the device supports multiple wavelength configurations, allowing users to select the most suitable setting based on the material being monitored. This adaptability enhances its versatility across different industrial applications.

In terms of usability, the IR Pyrometer for Glass Melting is designed with an intuitive interface that simplifies operation. Users can easily adjust settings and access critical data through a clear and readable display. The device is also equipped with calibration functions that ensure long-term accuracy, reducing the need for frequent maintenance. These features make it a valuable tool for both experienced professionals and those new to high-temperature measurement systems.

The application of this High Temperature IR Pyrometer extends beyond the glass manufacturing sector. It is widely used in industries such as metallurgy, ceramics, and chemical processing, where precise temperature monitoring is essential. In these fields, the pyrometer helps maintain optimal operating conditions, prevent equipment failure, and improve overall productivity. Its ability to function reliably in high-heat environments makes it a preferred choice for manufacturers seeking efficient and durable solutions.

User feedback highlights the reliability and performance of the Accurate IR Pyrometer. Many operators praise its ability to deliver consistent measurements even in challenging conditions. Some users have noted that the device’s durability and ease of use significantly reduce downtime and maintenance costs. Others appreciate the detailed reporting capabilities, which allow for better analysis of temperature trends and process improvements. Overall, the positive experiences of users reinforce the value of this high-temperature infrared pyrometer in industrial settings.

In May 2024, Laan Protection Technology Co., Ltd. completed the ISO 45001 system recertification. The audit team recognized the company's hazard identification and risk control in R&D, production and warehousing, confirming that the system operates effectively and records are complete. The company w

1. Infrared temperature measurement is a means of detecting equipment temperature anomaly. It is a non-contact temperature measurement method, which shows the temperature of the object by measuring the infrared light radiated by the object.Infrared is infrared radiation, infrared or infrared light f

The 14th Photonic China Expo, Beijing 2023, recently concluded with great success. This expo attracted numerous companies and experts focused on the infrared photonics field, bringing about new breakthroughs and collaboration opportunities for the industry. During the exhibition, we had the privileg

Changzhou Sijie Optoelectronics Technology Co., Ltd., a leading manufacturer of Infrared Pyrometer in China with an unwavering commitment to delivering superior accuracy and value, we are poised to meet this growing demand.In recent times, an increasing number of Indian companies have shown keen int